Small Custom Modular Gear Lathe Bronze Gears 0.5m Brass 1/30 Turbo Worm Gears

As one of the worm gears manufacturers, suppliers, and exporters of mechanical products, We offer worm gears and many other products.

Please get in touch with us for details.

Mail:[email protected]

Worm Gears

Worm gears are a type of gear that is commonly used in various industries, including automotive, aerospace, and manufacturing. They consist of a worm (a helical gear) and a worm wheel (a gear with a toothed rim). The worm gear is designed to provide high torque and reduce speed, making it an ideal choice for applications that require a high reduction ratio. In this article, we will explore the features and benefits of worm gears, and how they can be used in different applications.

One of the key advantages of worm gears is their ability to provide a high reduction ratio in a compact design. This is because the helical angle of the worm gear allows for a greater contact area between the gear teeth, resulting in higher torque output. Additionally, the design of the worm gear allows for a smooth and quiet operation, making it a popular choice for applications that require low noise levels.

Another advantage of worm gears is their ability to provide a self-locking mechanism. This means that the gear cannot be back-driven, which is particularly useful in applications where the load needs to be held in place without the need for external brakes or locking mechanisms.

Worm Gears Specifications

|

Product name

|

Custom Worms Gears Worm Gear Worm Gears

|

|

Material

|

Metal or Plastic

|

|

Finish

|

Clean or Customized

|

|

Process

|

Machining, Hobbing or Sintered or Injection molded

|

|

Tolerance

|

±0.1mm

|

Worm Gears Benefits

High torque: Worm gears can produce much higher torque than other types of gears. This makes them ideal for applications where a lot of force is needed, such as hoists, elevators, and machine tools.

Low speed: Worm gears can also reduce speed by a significant amount. This makes them useful for applications where it is necessary to slow down a moving object, such as power steering systems and lathes.

Smooth operation: Worm gears operate smoothly and quietly. This is because the teeth of the worm and worm wheel are not in direct contact with each other. Instead, they mesh together using a system of threads, which reduces friction and noise.

Compact design: Worm gears are relatively compact. This makes them ideal for applications where space is limited, such as in automotive power steering systems and machine tools.

Durability: Worm gears are very durable. They can withstand high loads and stresses, and they are also resistant to wear and tear.

Uses Of Worm Gears

Hoists and elevators: Worm gears are used in hoists and elevators to provide the high torque needed to lift heavy loads.

Machine tools: Worm gears are used in machine tools to transmit power to the cutting tool. This allows the tool to cut through materials with a high degree of precision.

Power steering systems: Worm gears are used in power steering systems to reduce the amount of force that the driver needs to apply to the steering wheel.

Lathes: Worm gears are used in lathes to control the speed of the cutting tool. This allows the tool to be moved at a precise rate, which is important for creating accurate cuts.

Winches: Worm gears are used in winches to provide the high torque needed to pull heavy loads.

Locking mechanisms: Worm gears can be used to create locking mechanisms that are very difficult to disengage. This makes them ideal for applications where security is important, such as in safes and security doors.

Maintenance tips for worm gears

Lubricate the gears regularly. The type of lubricant used will depend on the operating conditions and the gearbox design. However, in general, worm gears should be lubricated with a high-quality lubricant that is compatible with the materials of the gears.

Inspect the gears regularly for signs of wear and tear. Look for signs of cracks, chips, or excessive wear on the teeth of the gears. If any of these are present, the gears should be replaced.

Keep the gears clean. Dirt, dust, and other contaminants can build up on the gears and cause wear. Regularly clean the gears with a mild solvent or detergent.

Store the gears properly when they are not in use. Worm gears should be stored in a dry, cool, and clean environment. If the gears are stored in a humid environment, they should be coated with a protective lubricant.

We are one of the best worm gears manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

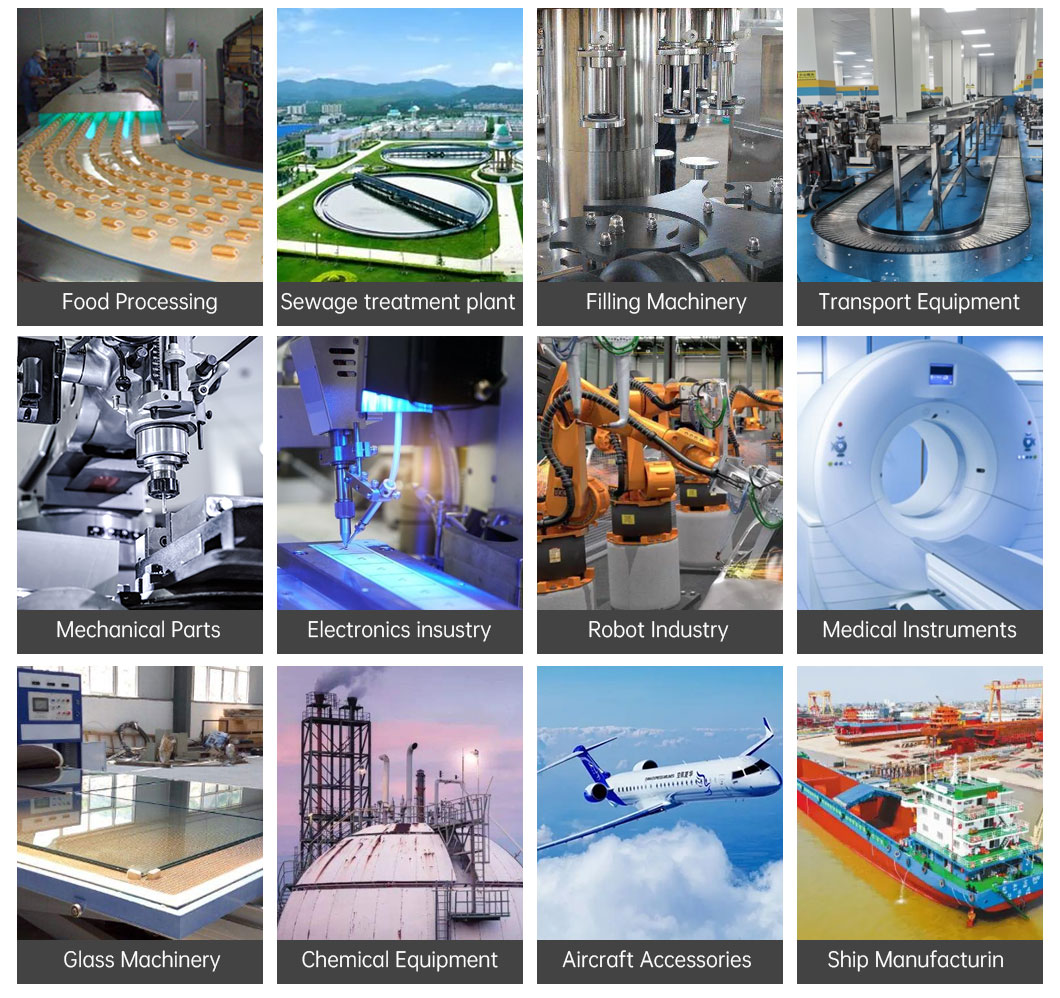

Application